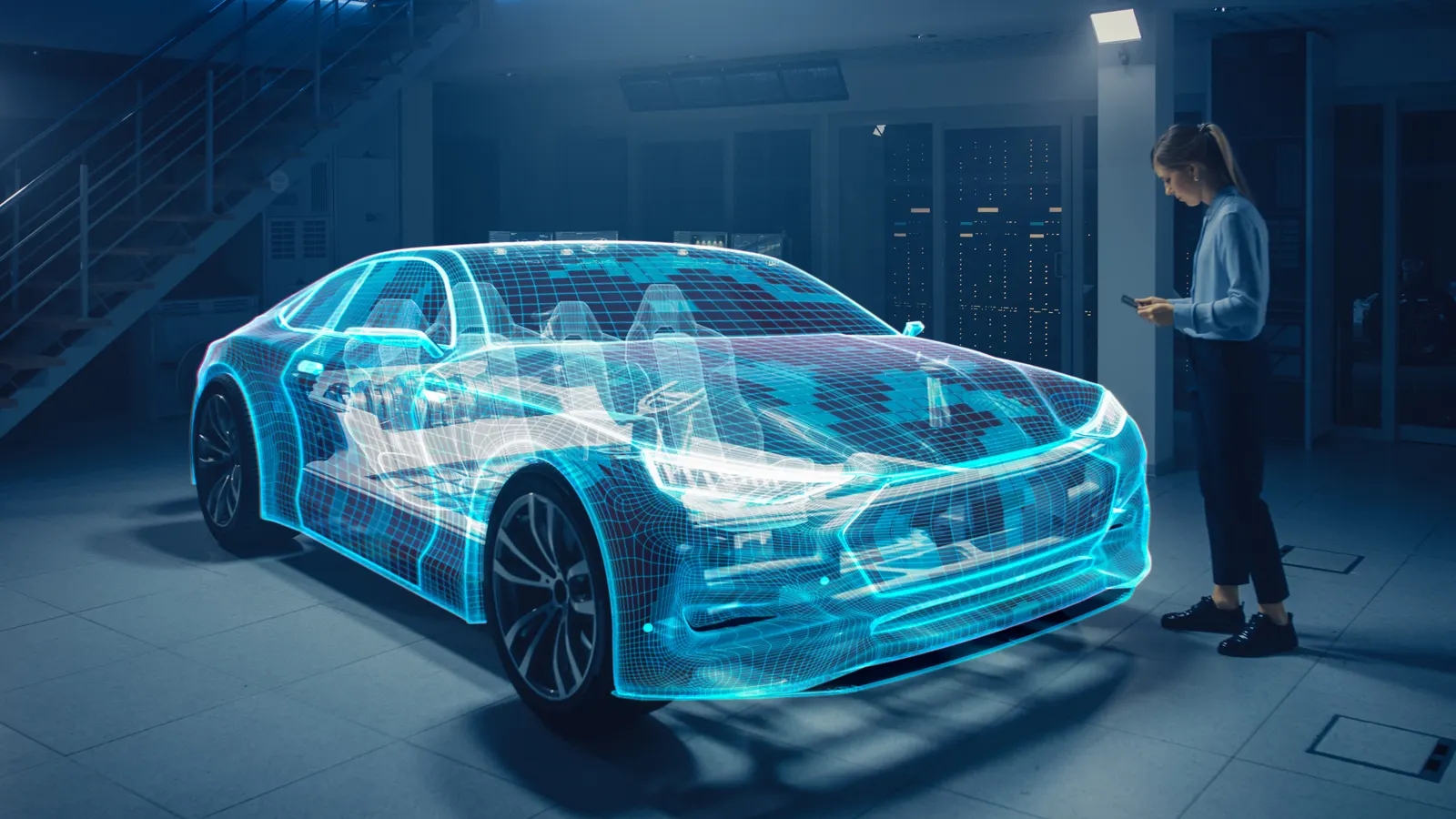

Électronique automobile

Sep 04 , 2025Solution d'inspection de propreté technique pour l'électronique automobile

1. Pourquoi une inspection de propreté technique pour l'électronique automobile est-elle nécessaire ?

1.1 Évitez les courts-circuits et les mauvais contacts, qui peuvent affecter la transmission du signal.

1.2 Empêcher la dégradation de la sensibilité des capteurs, comme la poussière recouvrant les caméras et les radars, ce qui peut affecter les fonctions de conduite autonome.

1.3 Empêcher une réduction de l'efficacité de la dissipation thermique, ce qui peut entraîner une surchauffe et des dommages.

1.4 Empêcher certaines particules de générer des signaux d’interférence électromagnétique, qui peuvent affecter le fonctionnement normal des composants électroniques.

1.5 Empêcher les particules métalliques ou les sels de réagir chimiquement avec les matériaux des composants, provoquant ainsi de la corrosion et des dommages.

1.6 Empêcher les contaminants de provoquer une dégradation des performances ou même une défaillance complète des composants électroniques dans les applications de haute précision.

2. Normes de contrôle de la propreté technique des composants électroniques automobiles

• JYBO CleanTech L'armoire d'extraction de propreté élimine les ions métalliques de surface et les particules supérieures à 100 μm, garantissant un fonctionnement stable des composants.

• Conforme aux normes internationales (VDA19 et ISO16232), améliorant la fiabilité, la dissipation thermique et le contrôle qualité.

3. Solution d'inspection de propreté technique JYBO CleanTech pour l'électronique automobile

Armoire de propreté des composants CCS

- Méthodes de nettoyage optionnelles : rinçage sous pression, ultrasons, rinçage interne, nettoyage par agitation, soufflage d'air

- Le soufflage d'air utilise de l'air propre et sans huile comme moyen de nettoyage à sec

- Élimine efficacement les contaminants particulaires, évitant ainsi les courts-circuits ou les dysfonctionnements

- Contrôle de propreté technique avec une efficacité de nettoyage élevée

- Armoire de propreté des composants fermés

- Chambre opératoire de classe 100 ou 1000